About us

We respond to customer needs with cold-rolled steel bar technology and a variety of processing technologies that we have acquired over many years.

Based on the manufacture of "polished steel bar," which are used in various fields such as automobiles, industrial machinery, and factory automation products, Ogiso Kogyo produces hard chrome plating, rolled ball screw processing, and machining in an integrated system.

Our professionals, who have a thorough knowledge of the characteristics of steel over a history of more than 80 years, respond flexibly to the diversifying needs of our customers.

Services

Production of polished steel bar

Most steel is manufactured as rolled steel, which is formed from raw materials such as iron ore and coke. These rolled materials have low processing precision, such as scratches on the surface, and cannot be used as is. Therefore, the role of Ogiso Kogyo is to improve the precision of rolled steel and produce "polished steel bar " with added functions.

Ogiso Kogyo has developed and manufactured a wide range of products, such as drawn steel bars, lathe-turned rolled steel bars, and ground steel bars, to meet the needs of our customers, utilizing the technology and know-how accumulated over our long history. Our commitment to quality and our production capacity of 7,000 tons per month enable us to meet the diversifying needs of the market.

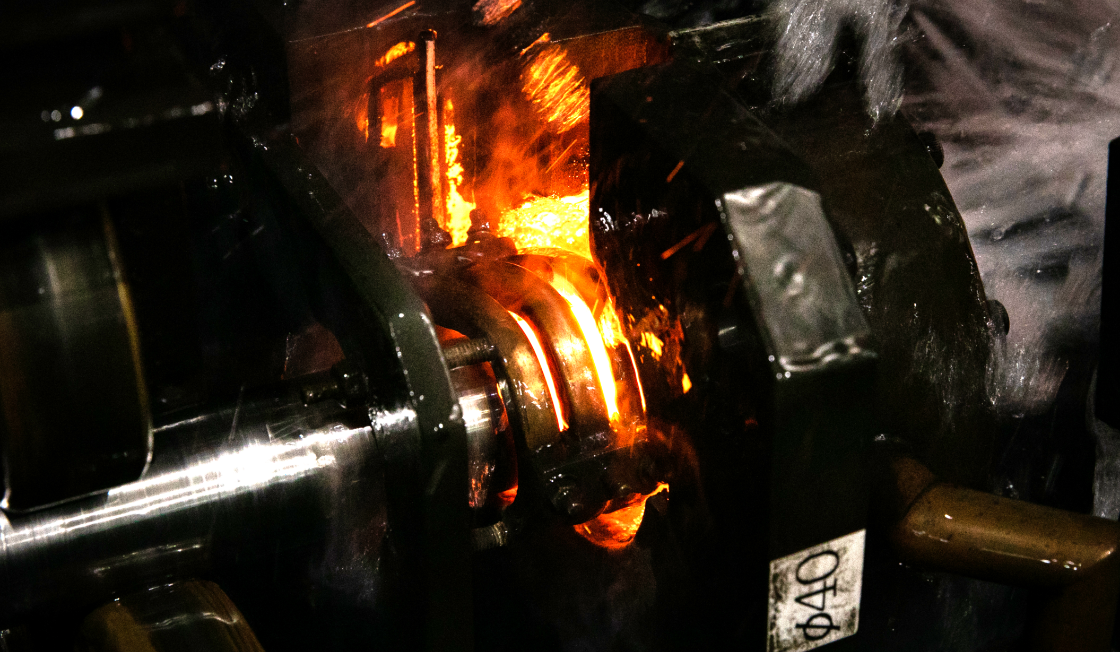

High-frequency quenching and hard chrome plating

Quenching and plating are processing technologies that improve the hardness and surface properties of steel. At Ogiso Kogyo, we have responded to the diverse needs of our customers by combining the technology of cold rolled copper bars with the processing technologies of high-frequency quenching and hard chrome plating.

Both the high-frequency quenching process and the hard chrome plating process have their own in-house processing facilities and can handle a variety of lengths and diameters, from 6m long materials to machined parts. In addition to delivering products that are easy to use at the customer's production site, Ogiso Kogyo also provides products that can be used with confidence through a quality assurance system based on in-process quality data and product test data. One of the features.

In addition to the production of cold-polished steel, we continue to earnestly meet the needs of our customers, expand our product lineup, and improve added value.

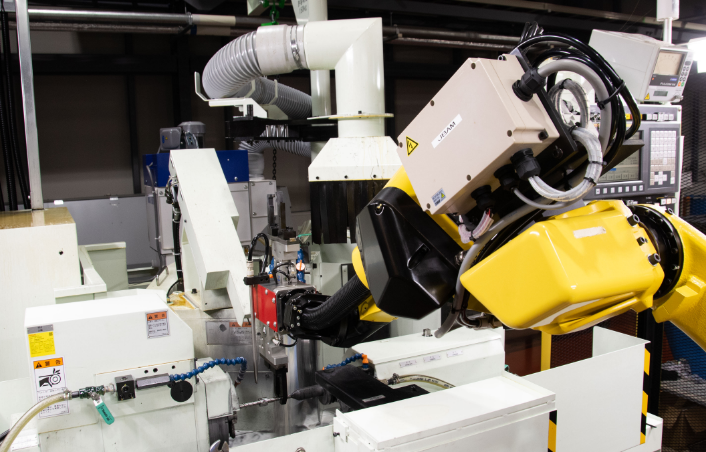

Rolled ball screw machining and machine parts machining

Another feature of Ogiso Kogyo is that we provide products processed from polished steel bar to meet a variety of needs.

We can handle shaft end machining using a CNC lathe, drilling using a gun drill, and plane machining using a machining center. We will process the product into the specified shape and deliver it to you so that you can use it as is. In particular, we have one of the highest production capacities in Japan for long thread rolling machines for manufacturing pole screws and pole screw nut manufacturing processes.

The advantage for our customers is that we can offer products with high precision and little variation, because we provide integrated processing services that shorten lead times and are processed by professionals who are thoroughly familiar with the characteristics of steel.

Strength

Production capacity of 7,000 tons per month

We have four production bases in Aichi and Mie, including the Nagoya Plant where the company was founded. With a monthly production capacity of 7,000 tons, we manufacture a wide range of products. In particular, we produce a wide range of products, such as thread rolling pole screws The product can produce more than 10,000 pieces of 3m timber per month.

The Mie Plant, which specializes in long bar products, is equipped with a material receiving yard capable of stocking up to 2,000 tons of rolled materials. Optimized production line layouts ensure smooth flow and shortened lead times.

At the Kasugai plant, which processes shaft ends and ball screw nuts, we are promoting automation using robots and producing machined parts with minimal variation in a constant-temperature plant that is maintained at a constant temperature throughout the year.

High-precision ground shafts even at long lengths

We are highly evaluated by our customers for the dimensional accuracy of long grinding.

We have more than 20 centerless grinding machines as long grinding equipment. All facilities are equipped with laser-type automatic outer diameter measuring instruments to automatically measure and record the outer diameter of the entire product. We guarantee an outer diameter accuracy of 3μm or less for 3m materials, and mass production is also possible.

Our ability to guarantee this accuracy in the production process of long grinding products is a major feature of our company. Ogiso Kogyo's strength lies in the fact that we have integrated production in all processes and ensured quality in each process.

Thorough quality control and warranty system for peace of mind

Strength of our company is the quality control system cultivated in the automobile industry, which requires strict quality control.

In addition to quality assurance in the manufacturing process, we also have a thorough control of the process and traceability of our products, which enables us to provide our customers with the highest quality products. We deliver products that are 100% safe to use.

In addition, the laboratory, which specializes in testing and inspection, is equipped with a variety of testing machines and inspection equipment to provide high-precision testing and assurance in accordance with product characteristics and customer needs.

Visualization of production system or BCP

We were the first in the industry to introduce a core system that connects all production bases via the cloud. By centrally managing the production system, including inventory, we are promoting lean manufacturing.

By sharing information using digital technology, we are improving the level of quality assurance and building a system that can ensure a stable supply without delaying production in the event of an emergency.

Actively challenging new technologies and processes

In addition to the quality requirements of our products, another of our strengths is our ability to understand the needs of the customers who use our products and to develop our manufacturing processes.

We strive to make proposals that exceed our customers' expectations by utilizing the knowledge and expertise we have acquired through our involvement in various fields of products, not limited to cold rolled steel bars.

We are also actively trying to introduce new technologies both in Japan and overseas, and we continue to improve our technologies to meet all expectations.

Production of environmentally friendly products

We are implementing a variety of initiatives to achieve sustainable growth while taking the environment into consideration, including addressing climate change and reducing waste.

For example, we are planning to install solar panels at all of our plants in order to use sustainable natural resources. We also aim to solve the problems of the entire planet.

Manufacturer and processor of cold rolled steel bars and precision shafts

Manufacturer and processor of cold rolled steel bars and precision shafts